Manufacturing & Industry 4.0 Solutions

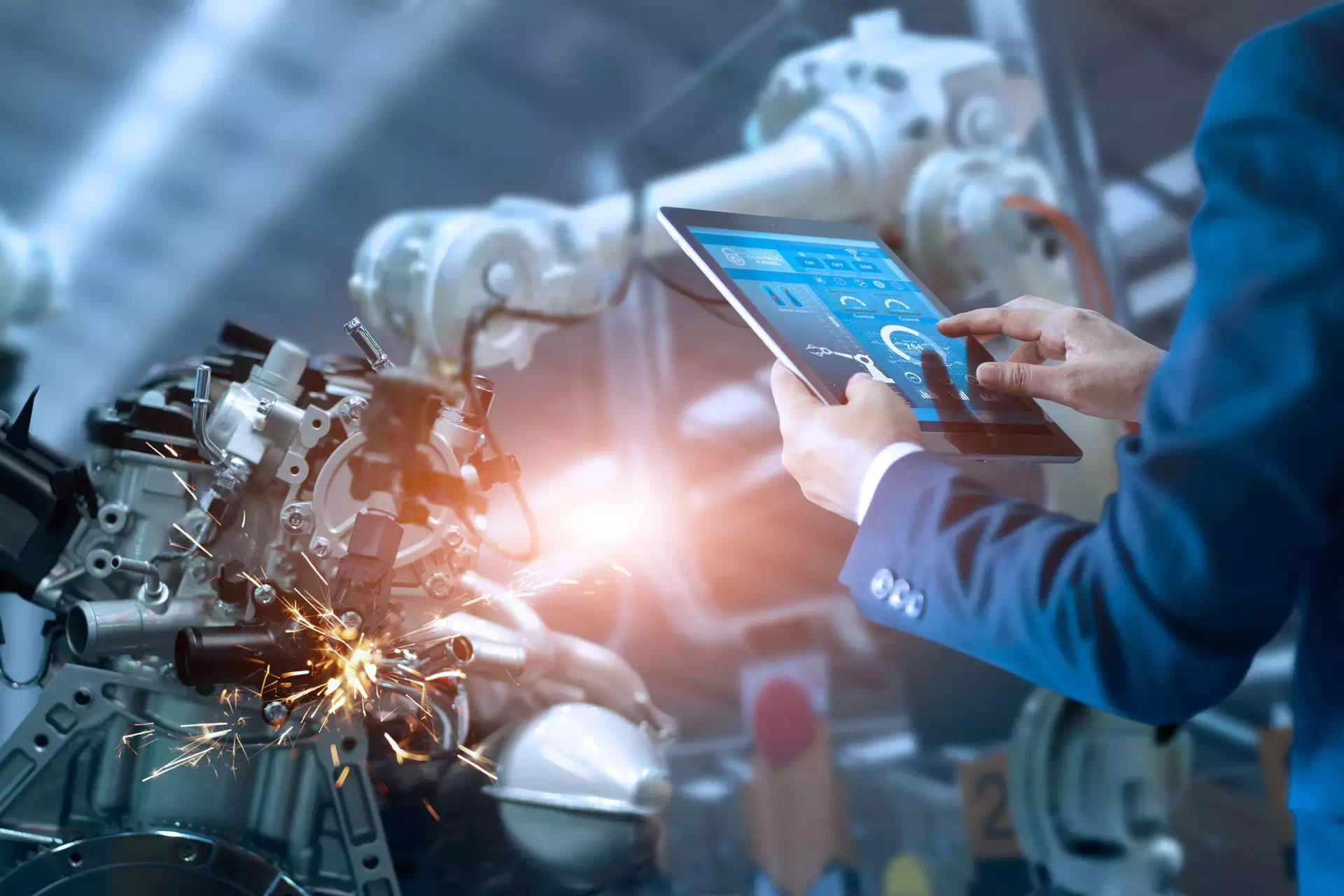

The development in Industry 4.0 and the convergence of disruptive technologies are modifying the manufacturing industry – machines getting intelligent and digitally manageable, units becoming dynamic, data-driven automatically, supply chain and operations getting built up by advanced AI and AR.

The enhancement is creating knowledgeable opportunities for all traditional manufacturing companies – by advocating the value chains, drawing efficiency, transforming products into services, and getting manufacturers even closer to their consumers.

Most of the best manufacturing companies globally have partnered with Cinntra Infotech to bring about transformative business ethics through transforming operations, innovative products, minimizing unplanned downtime, creating new business models, and increasing asset utilization.

When we refer to industry-specific manufacturing solutions, the work starts right from manufacturing products to design, supply chain to services. Cinntra's robust manufacturing consulting services allow manufacturers to deploy best-in-class solutions for their organization. With the assistance of technologies like data analytics, IoT, AI & automation, cloud, etc.

We have been helping manufacturing industries digitally transform their organization for almost a decade. Cinntra Infotech as a technology partner provides IT consulting services to all manufacturing industries. With extensive years of experience, we constantly serve our clients with new emerging technologies & innovations so they meet the standard digital transformation of their operations to succeed in the increasingly volatile & dynamic market.

Our Solutions

Developing digital capabilities to gain an edge in a devastating market. We offer the best in Industry service according to your business needs. Now, scale-up your manufacturing business and gain instant productivity with Cinntra's end-to-end software solutions. Our manufacturing 4.0 technology services purely aim to support companies' channels of technology, effortlessly improve efficiencies, and gain proper visibility across all the enterprise functions. Our expert team of professionals will help you drive growth by simply combining the industry's best practices together with technological excellence which will enable you to process developments.

Get customizable services according to your business requirements

Talk to our expertSegment

Warehouse Management

Maximize the labor services and minimize antiquation with the warehouse management solution. The feature offers you a real-time transaction process, storage information & strategies, task management, and much more. With the warehouse management feature keep an eye on all the raw materials and maintain your stocks.

Manufacturing Sales Enablement

Cinntra Infotech offers the best industry-leading sales solutions that will empower manufacturing enterprises that drive innovative business models & deliver unbelievable buyer experiences. Never miss a deal with us, grab all your deals with high-end technology.

Enterprise & Supply Chain Management

Impress and sustain your customers with flexibility and responsive supply chain management. We at Cinntra help your organization to solve critical supply chain challenges while being cost-effective in the most efficient manner.

Inventory & Order Management

Untangle your inventory and manage your orders from accepting - delivering orders. Our solution will help your organization to reduce inventory and operational costs. Now, keep your customer intact with timely deliveries, order insights, and more.

Product Lifecycle Management

Now easily, minimize product cycle times, enhance your processes, and seamlessly boost revenue while upgrading customer satisfaction and increasing your market value with the product lifecycle management solutions.

Dolori Architecto

Hic molestias ea quibusdam eos. Fugiat enim doloremque aut neque non et debitis iure. Corrupti recusandae ducimus enim.

Maximize Your Business Productivity with Industry 4.0 Solutions

-

How does Industry 4.0 impact the Manufacturing Industry?

Industry 4.0 boosts revenue and profits by enhancing production efficiency, quality, & enabling predictive maintenance, reducing downtime and long-term capital expenses.

-

How to Implement Industry 4.0 in the Manufacturing Industry?

Progress toward Industry 4.0 Implementation in 4 steps: data collection, digital processes, predictive maintenance, and self-adjusting machines.

-

How Industry 4.0 Transforms Manufacturing?

Industry 4.0 enables lean manufacturers to optimize time, cost, energy, materials, and human resources, particularly with the concurrent adoption of various IR4 technologies.

-

Is Industry 4.0 the same as Smart Manufacturing?

While 'Smart Factory' and 'Smart Manufacturing' have global usage, 'smart industry' is more region-specific and essentially synonymous with Industry 4.0, or Industrial IoT.

-

What are the Principles of Manufacturing Industry?

Industry 4.0 has 6 principles: interconnectivity, information transparency, decentralization, real-time capabilities, technical support, service orientation, & modularity.

-

Why is Industry 4.0 known as Automation?

It's not just mechanization; control and information systems outperform humans in handling complex processes cost-effectively, known as industrial automation 4.0.