How does SAP Business One help chemical companies manage complex inventory and production

Many businesses across various sectors are actively seeking methods to reduce costs while enhancing efficiency. The major challenge is particularly addressed in the chemical industry due to the complexity of its production processes.

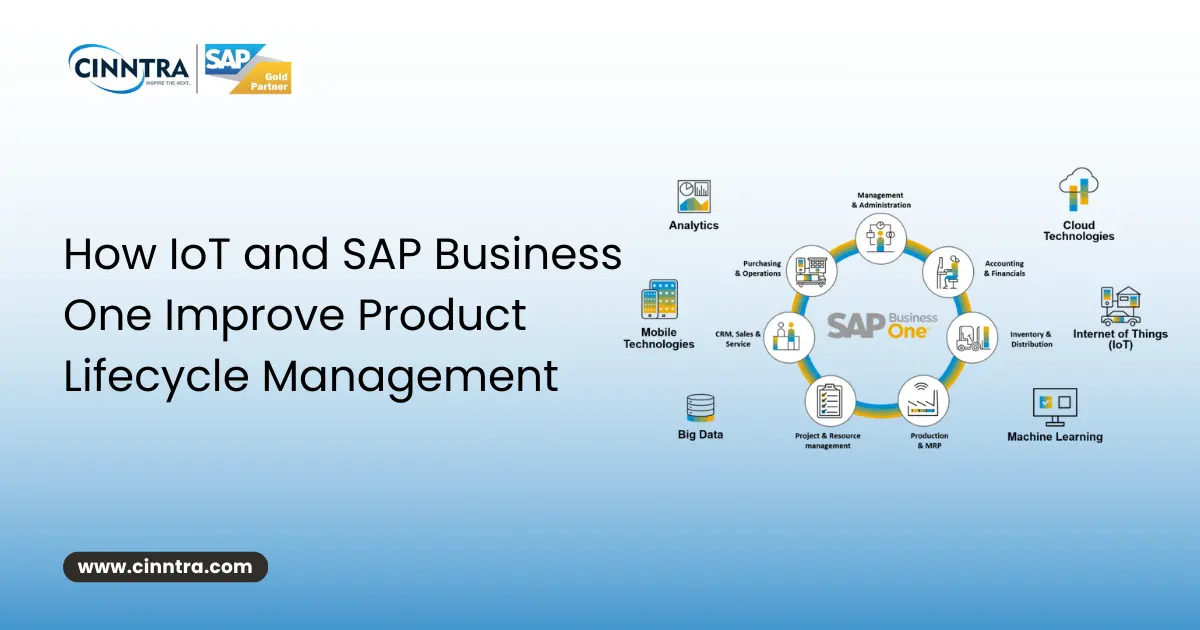

One effective solution that many chemical companies are adopting is SAP Business One Implementation. This software enables organizations to streamline their operations, boost efficiency, and lower production costs.

SAP Business One, specifically designed for chemical product management, aids companies in cutting expenses and increasing productivity. We will also explore SAP ERP caters specifically to the unique needs of the chemical industry.

Top Ways SAP Business One Enhances Complex Inventory and Production by Chemical Companies

SAP Business One in the chemical industry has advanced technology applications to enhance business efficiency while mid-market manufacturing firms frequently struggle to keep the progress in check.

The chemical industry is heavily regulated by necessitating management of production processes, inventory, and quality assurance. SAP Business One provides a comprehensive integrated system that allows companies to oversee all business operations from raw materials to finished products.

This integration optimizes the supply chain and minimizes waste. Key features include monitoring hazardous materials and addressing safety concerns, specifically tailored for the chemical sector.

Chemical manufacturing involves numerous operations that benefit significantly from the SAP Business One platform. Communication breakdowns among professionals at various production levels can delay product lifecycles, regardless of manufacturing efficiency.

One-Point Integration

SAP Business One's primary feature is its centralization, which allows all departments within a company to access a single point of contact. Each team can share relevant information through their channels by ensuring that data is stored in a centralized location accessible to everyone.

The sales team can access this information directly when the marketing team collaborates with a customer and records the details. In contrast, previous systems required teams to retrieve data from individual users. It leads to data duplication and unnecessary storage use. SAP Business One enhances efficiency by centralizing interactions and reducing data redundancy.

Real-time Updates

Implementing SAP Business One as an enterprise software solution establishes a framework for real-time updates and information sharing, facilitating collaboration among teams.

Consider a scenario where a customer representative completes a deal. The customer information can be promptly recorded and updated on the platform, allowing the production team to begin their work even before the representative returns to the office. Similarly, when the sales team logs updates about sales activities, the marketing team can quickly access this data to generate reports that reflect the organization’s overall performance.

Inventory Management

The SAP Business One platform is designed for automated inventory management to ensure sales are made correctly and inventory levels are updated automatically. If stock levels fall below a specified threshold notifications are sent to the relevant personnel.

SAP Business One implementation allows teams to monitor organizational performance and sales pipelines effectively. It helps them identify slow-moving products while ensuring that production aligns with demand for high-selling items.

However, SAP Business One supports efficient inventory management by ensuring that supply meets market demand effectively.

Streamlined Production Processes

Implementing SAP Business One with the intent of optimizing production processes. The software automates many manual tasks including order processing and production scheduling to minimize errors and save time.

This automation enhances productivity while reducing labor costs by making it a vital asset for companies. It aims to lower production expenses through an efficient ERP system.

Streamlined Production Orders

With SAP Business One implementation, companies can create production orders that track specific quantities of finished products. These orders contain vital information such as item details, quantities, due dates, and routing instructions. This structured approach ensures that production processes are organized and transparent.

Material Requirements Planning (MRP)

The MRP functionality determines the materials necessary for production based on demand and current inventory levels. It generates purchase orders or production orders to fulfill material needs, ensuring that resources are always available for manufacturing processes.

Capacity Planning and Resource Management

SAP Business One Implementation enables effective capacity planning, allowing companies to analyze the utilization of work centers and resources. This helps identify potential bottlenecks and optimize resource allocation, ensuring smooth production scheduling.

Quality Control

The system provides tools for real-time tracking of production activities on the shop floor. Companies can record material consumption, labor hours, and machine time against production orders. Additionally, quality control processes can be defined to ensure that products meet established standards.

Impart Growth with SAP Business One ERP System!

Large chemical companies often have dedicated teams and advanced technology solutions to enhance business efficiency for SMEs. However, maintaining quality control, effective traceability, and regulatory compliance can be challenging for these smaller organizations. This hinders their ability to innovate something substantial for the marketplace.

The chemical industry is heavily regulated by necessitating systemized management of production processes, inventory, and quality assurance. SAP Business One is therefore considered the best ERP for chemical manufacturing that allows companies to manage all business operations from raw materials to finished products. This integration optimizes the supply chain to minimize waste.

Communication breakdowns among professionals at various production levels can delay product lifecycles regardless of manufacturing efficiency.

SAP Business One for chemical product management is an effective solution that enables businesses to achieve this by enhancing inventory management and delivering real-time insights. Further, it ensures regulatory compliance and simplifies production workflows.

0 Comments