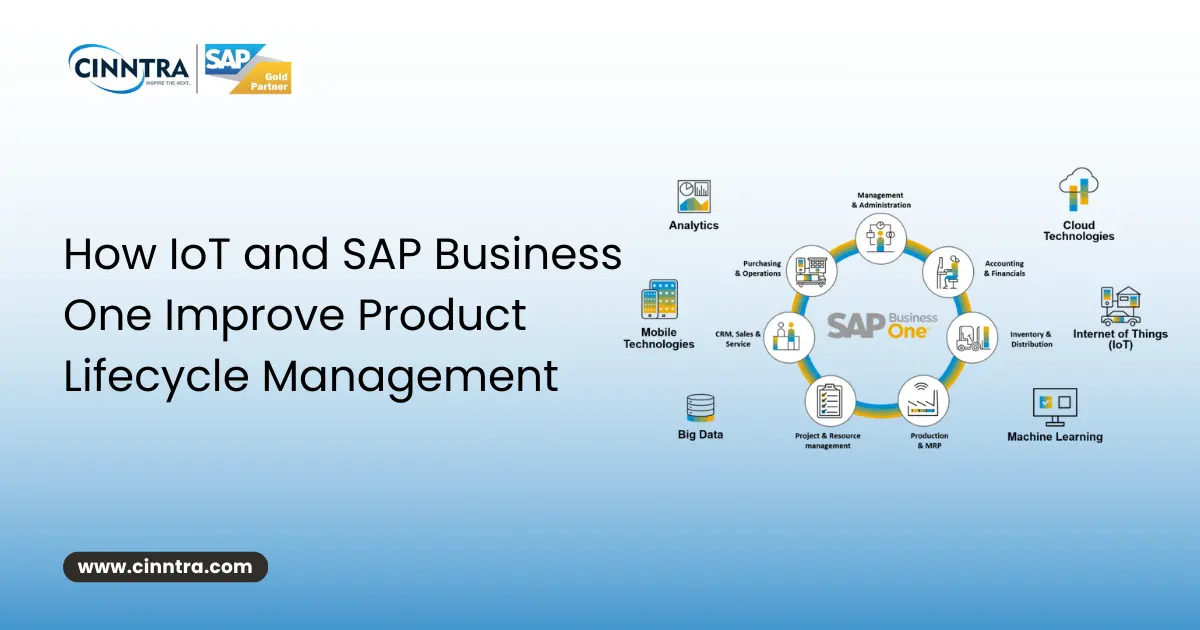

How IoT and SAP Business One Improve Product Lifecycle Management

More than 70% of manufacturers claimed that their decision-making and product quality have improved due to real-time information streamed from various connected devices. Businesses today have borne the negative impacts of reactive processes and fragmented systems, especially due to increased global competition.

The evolving practices of intelligent manufacturing require integration, visibility, and precision at every stage of the product lifecycle. This challenge is precisely where the integration of SAP Business One with IoT system solution has an advantage.

Real-time sensor data combined with a unified ERP provides companies with relevant and actionable insights in addition to deregulating operational silos during every phase of the product lifecycle management, be it design or decommissioning.

The Changing Role of Product Lifecycle Management in Manufacturing.

Modern manufacturing would be a chaotic environment if there was no structured Product Lifecycle Management (PLM) Solutions system in place. A well-implemented PLM software solution takes care of a product from an idea to its engineering and design, mass production, servicing, and even end-of-life recycling. The lack of centralized PLM systems concluded with uncontrollable communication gaps and excess duplication of data is a common problem for many manufacturers.

PLM-enabled companies need to be focused on control, consistency, and cross-functional relations maintained with other advanced systems like SAP Product Lifecycle Management.

PLM solutions provided by SAP include meticulous version history, document control, and cohesive workflows that facilitate uniformity concerning product data across various functions. All engineering, production, sales, and service teams operate with the same up-to-date data which accelerates time to market and decreases error probability.

Why IoT is Critical in Manufacturing?

The Internet of Things (IoT) brings forth a system of devices that have been equipped with sensors and are able to communicate and transmit data in real time. In manufacturing, IoT supervises equipment status, environmental conditions, and supply chain activities. Companies not leveraging this technology are bound to have a constrained vision of their operations. On the other hand, with the adoption of SAP Business One for Smart Manufacturing, businesses gain foresight, optimized processes, and better asset management.

Proactive, data-driven operations powered by IoT are enabling manufacturers to eliminate breakdowns, reduce waste, and adjust production schedules according to real-time demand signals. These advancements signify a transformative shift in the industry—moving away from traditional reactive manufacturing toward a more agile, predictive, and IoT-driven approach.

SAP Business One IoT Integration: Constructing Intelligent Manufacturing Frameworks

The incorporation of IoT into ERP systems such as SAP Business One creates a digitally integrated and connected setting for manufacturers. This advanced ecosystem integrates real-time data from the shop floor with enterprise-level decision-making, enabling faster responses to disruptions and driving improved product quality and outcomes. Through SAP Business One IoT integration, manufacturers optimize the flow of data from machines to management dashboards.

Core Benefits of IoT + SAP Business One:

-

Remote real-time monitoring of production processes.

-

Predictive maintenance smart alerts.

-

Automated quality assurance processes.

-

Live inventories of products with logistics tracking.

-

Improved compliance and traceability.

With the benefits, businesses can have improved product quality, customer satisfaction, and cost-efficient operations. Manufacturers can synchronize production programs with inventory levels, equipment tolerances, and the monitoring of every product’s progress through the supply chain.

Examining the Product Lifecycle through the Lens of IoT Integration with SAP

As we already discussed, PLM consists of a series of critical phases. With IoT-enabled insight on these phases, and integrated with SAP Product Lifecycle Management, manufacturers build a continuous feedback loop that improves product performance and process efficiency.

-

Concept and Design

An interdisciplinary team captures the inputs from previous versions of the product, product feedback from customers, and market research. Because of IoT data, design choices can indeed consider the actual usage conditions of the product. SAP tools ensure that preliminary assessments on feasibility, cost estimates, and prototype viability consider scope creep by confirming that development aligns with business objectives.

-

Engineering and Prototyping

Based on the product specifications, engineers build smart prototypes integrated with IoT sensors to test durability, temperature thresholds, and stress points. These metrics can be fed directly into SAP Business One to design alterations and BOM updates instantly.

-

Manufacturing and Quality Control

By employing SAP Business One for Smart Manufacturing, companies automate the setting up of production tracking flows and real-time inspections based on sensor input. Data-driven quality control checks are performed during production instead of after, thus reducing errors and costly rework.

-

Distribution and Service

In the warranty phase, IoT devices monitor shipping conditions and product usage. These data insights enable proactive planning, and documentation updates, as well as informing future product design decisions.

-

End-of-life and Recycling

With exact information, it is easier to make well-informed judgments on sustainability reporting and product decommissioning dates. They are able to manage post-consumer product reuse and recycling as well as compliance with environmental regulations.

Smart Manufacturing at Scale with SAP Business One

While many ERP solutions serve large corporations, SAP Business One for Smart Manufacturing caters to the specific needs of small to medium-sized businesses (SMBs) looking to grow in a cost-effective manner. It streamlines essential processes such as production scheduling, material needs, warehouse operations, and financial oversight. Recent updates from SAP enable further integration of the Manufacturing Execution System (MES), which permits managers to supervise activities through a single operational dashboard.

These enhancements enable businesses to:

-

Implement digital transformation strategies for outdated systems.

-

Monitor productivity on the shop floor.

-

Mobilize execution of production orders via smart devices.

-

Participate in automated supplier collaboration workflow processes.

Best of all, SAP Business One becomes an ideal system foundation for intelligent IoT integration into everyday business activities, especially for SMBs looking for operational simplicity.

Using the IoT for Real-Time Feedback and Predictive Analytics

Manufacturing is past the point of using retrospective reports. Today's decision-makers require real-time data to guarantee optimal performance in every workflow. With SAP Business One integration with IoT, sensors are able to stream data into the ERP platform for organizations to be able to analyze trends and preempt breakdowns as well as inefficiencies before they come out in full scale.

Some Examples of IoT-Driven Insights in SAP Business One:

-

Machines exceeding heat thresholds trigger automatic service requests.

-

Inventory running below reorder points initiates purchase requisitions.

-

Production line abnormalities generate quality alerts for inspections.

This insight reduces material waste, increases equipment reliability, and speeds up response times—all of which drive better product lifecycle outcomes.

Upcoming Developments in SAP Product Lifecycle Management

SAP has been keen on transforming businesses digitally, and this is well-captured in their PLM roadmap which illustrates a move towards hyper-connectivity and automation. Important automation components include:

-

Digital Twins: Emulation of physical products maintained to enhance performance.

-

AI Forecast-based Planning: Improved product development, and precise inventory planning.

-

Sustainability Tracking: Assessment tools for measurement of environmental impacts on a product through its life cycle.

-

Cloud-first Distributed Systems: Effortless and automatic upgrades lead to seamless collaboration worldwide, advanced infrastructure, and broad access to SAP products.

Through these changes, intelligent growth, and sustainability, SAP Product Lifecycle Management will become an essential component of adaptive resilient-centered manufacturers.

Achieving Lifecycle Excellence with IoT and SAP

Integrating IoT with any ERP system is neither optional nor aspirational as modern IoT-enabled manufacturing technologies now drive unparalleled levels of productivity. By harnessing intelligence at all stages of a product’s lifecycle, companies transcend traditional benchmarks of output to redefine efficiency and quality. Manufacturers empowered by IoT integration with SAP Business One are now able to act on data, reduce uncertainty, and enhance customer satisfaction.

Now, with advanced SAP Product Lifecycle Management capabilities, businesses can integrate and orchestrate design, production, and service into an insight-driven strategy. At the same time, SAP Business One for Smart Manufacturing enables manufacturers of all sizes to remain competitive in an era where speed and insight are fundamental to survival.

The combination of SAP and IoT is the answer to the growing need for advanced, greater sustainable innovations. This synergy is what stands at the heart of unprecedented manufacturing excellence.

0 Comments